GMSL vs FPD-Link vs MIPI A-PHY: How Product Teams Choose the Right Camera SerDes

Huy Duong

•

28 December 2025

•

4 mins

As products add more cameras—often placed far from the main processor—connectivity becomes a product architecture decision, not just a hardware detail.

Automotive systems, robots, industrial machines, and wearables all face the same question:

How do we reliably connect remote cameras without redesigning the entire platform?

The answer is SerDes. But choosing which SerDes technology—GMSL, FPD-Link, or MIPI A-PHY—has long-term implications for cost, risk, and roadmap flexibility.

Why Traditional MIPI Is Not Enough

MIPI CSI-2 and DSI were designed for short, internal connections—like phone cameras or laptop displays that sit just centimeters from the processor.

They work extremely well inside a device. They struggle once the camera moves outside the board.

Limitations of Traditional MIPI

- Very short reach (typically <20–30 cm)

- Sensitive to electrical noise

- Fragile connectors and cables

- Poor fit for multi-camera or harsh environments

For products with remote cameras, these limitations quickly become blockers.

What SerDes Changes

Traditional MIPI is limited to short board-level connections, while SerDes enables long-reach, robust camera links.

Traditional MIPI is limited to short board-level connections, while SerDes enables long-reach, robust camera links.

SerDes (Serializer / Deserializer) converts short-range MIPI signals into a long-reach, robust link, then converts them back near the processor.

From a product perspective, SerDes enables:

- Cable lengths of meters, not centimeters

- Single-cable designs (data + power + control)

- Stable performance in noisy environments

- Scalable multi-camera systems

- Minimal impact on SoC software

Traditional MIPI is a board-level interface.

SerDes turns it into a system-level architecture.

Which SerDes?

Once a team accepts that native MIPI isn’t sufficient for remote cameras, the decision shifts from whether to use SerDes to which SerDes strategy to adopt.

This is where GMSL, FPD-Link, and MIPI A-PHY diverge.

- GMSL and FPD-Link extend MIPI using proprietary, mature ecosystems focused on speed and reliability.

- MIPI A-PHY aims to standardize long-reach connectivity and reduce vendor lock-in over a product’s lifetime.

All three solve the same technical problem—but they make very different business and roadmap tradeoffs.

GMSL (Gigabit Multimedia Serial Link)

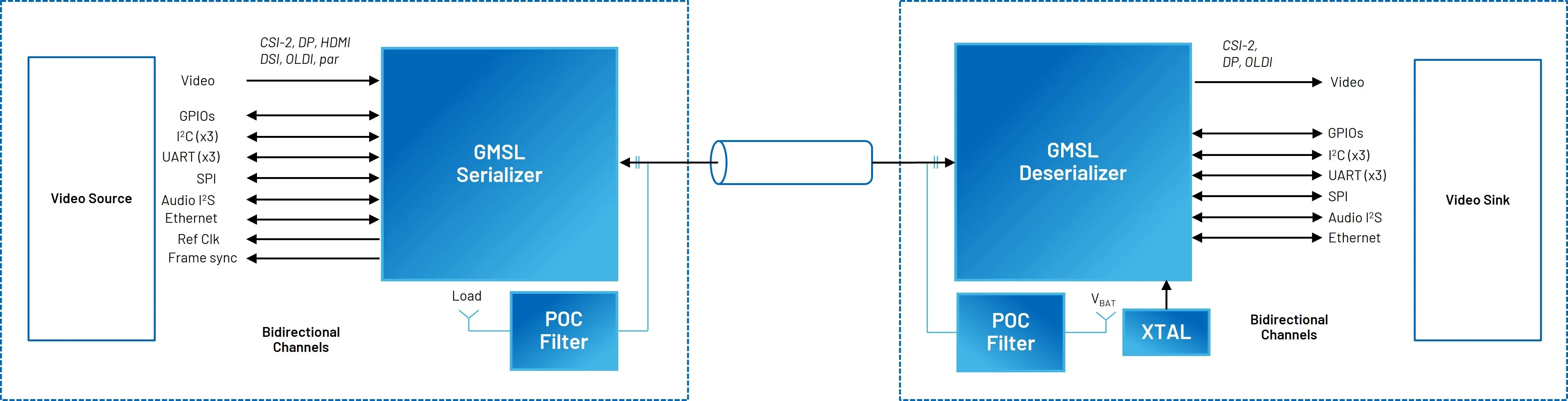

Typical GMSL setup with a remote camera module connected to a central processor over a single cable.

Typical GMSL setup with a remote camera module connected to a central processor over a single cable.

Owned by: Analog Devices (formerly Maxim)

What it is:

A proprietary SerDes technology purpose-built for cameras and high-speed sensor data.

Why product teams choose it

- Deployed in millions of vehicles

- Very low latency

- Transparent MIPI CSI-2 integration

- Power, data, and control over one cable

Tradeoffs

- Strong vendor lock-in

- Limited interoperability

- Premium BOM cost

Best fit

Products that prioritize low risk and fast time-to-market.

FPD-Link

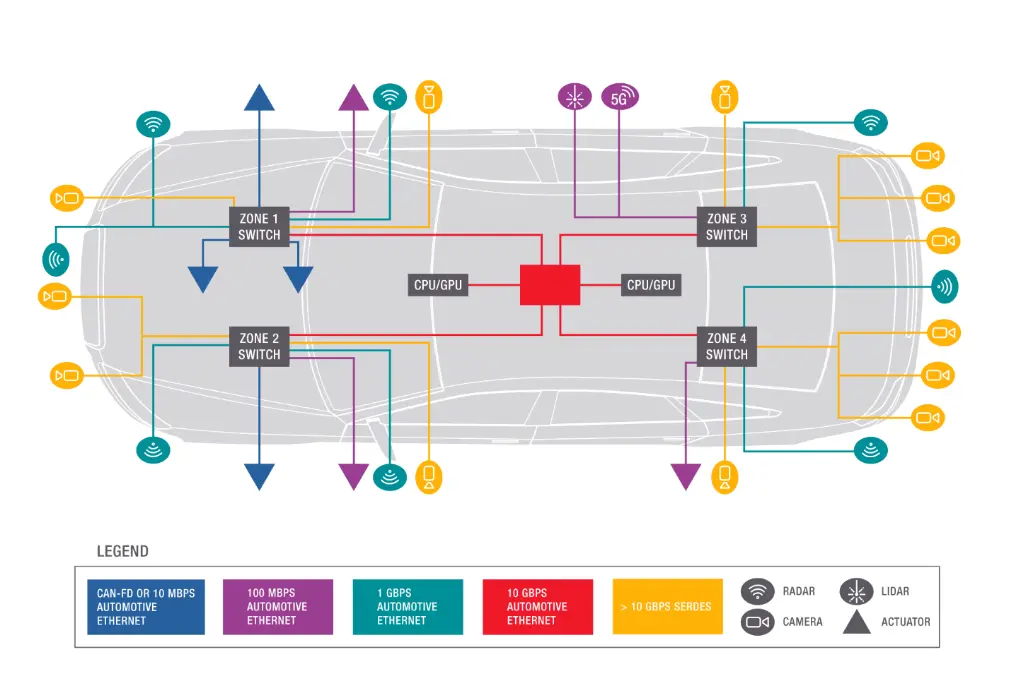

FPD-Link architecture commonly used in automotive and industrial camera systems.

FPD-Link architecture commonly used in automotive and industrial camera systems.

Owned by: Texas Instruments

What it is:

A long-standing SerDes family originally developed for displays, now widely used for cameras.

Why product teams choose it

- Automotive-proven and highly reliable

- Strong multi-camera support

- Seamless MIPI CSI-2 compatibility

- Tight integration with TI platforms

Tradeoffs

- Proprietary ecosystem

- Similar lock-in profile to GMSL

- Comparable cost structure

Best fit

Products already aligned with TI supply chains or platforms.

MIPI A-PHY

MIPI A-PHY standardizes long-reach camera connectivity for future automotive platforms.

MIPI A-PHY standardizes long-reach camera connectivity for future automotive platforms.

Owned by: MIPI Alliance (open standard)

What it is:

The first standardized long-reach physical layer designed specifically for automotive and industrial camera systems.

Why it exists

- Reduce fragmentation

- Enable multi-vendor interoperability

- Support long product lifecycles

- Meet future safety requirements

Advantages

- Open standard

- Designed for functional safety

- Long-term roadmap flexibility

Current limitations

- Ecosystem still emerging

- Fewer production deployments today

- Slightly higher integration effort

Best fit

Products with long lifecycles and platform reuse goals.

Side-by-Side Comparison (PM View)

| Criteria | GMSL | FPD-Link | MIPI A-PHY |

|---|---|---|---|

| Ownership | ADI (Proprietary) | TI (Proprietary) | Open Standard |

| Market maturity | Very high | Very high | Emerging |

| Vendor lock-in | High | High | Low |

| Latency | Ultra-low | Ultra-low | Ultra-low |

| SoC integration | Very easy | Very easy | Easy (growing) |

| Automotive adoption | Widespread | Widespread | Growing |

| Long-term flexibility | Limited | Limited | High |

How Product Teams Should Decide

Choose GMSL or FPD-Link if:

- Time-to-market is critical

- You need proven reliability today

- Vendor lock-in is acceptable

- Product lifecycle is 3–7 years

Choose MIPI A-PHY if:

- You’re building a long-lived platform

- Interoperability matters

- You want supplier flexibility

- Future automotive safety requirements are a priority

Final

GMSL and FPD-Link win on maturity and speed.

MIPI A-PHY wins on openness and future-proofing.